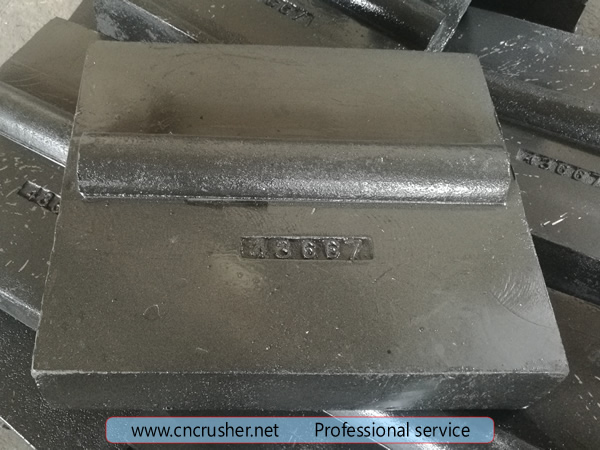

Wear plate for ball mill

Ball Mill: A Comprehensive Overview

A ball mill is a highly efficient grinding machine designed to grind and blend materials for use in various industrial processes, including mineral dressing, paint manufacturing, pyrotechnics, ceramics, and selective laser sintering. The operational principle of a ball mill is based on impact and attrition, where size reduction is achieved through the impact of grinding balls as they drop from near the top of the rotating shell.

The ball mill comprises a hollow cylindrical shell that rotates around its axis, which can be either horizontal or slightly inclined. The shell is partially filled with grinding media, typically balls made from materials such as steel (including chrome steel), stainless steel, ceramic, or rubber. The inner surface of the cylindrical shell is often lined with abrasion-resistant materials like manganese steel or rubber. Rubber linings are particularly advantageous as they significantly reduce wear and tear, thereby extending the lifespan of the mill. The dimensions of the mill are generally proportional, with the length being approximately equal to its diameter.

In the case of continuously operated ball mills, the material to be ground is fed into the mill through a 60° cone on the left side. The ground product is then discharged through a 30° cone on the right side. As the shell rotates, the grinding balls are lifted on the rising side of the shell and cascade down from near the top, impacting the material to be ground. This continuous motion results in the reduction of solid particle sizes through repeated impact and attrition.

Ball mills are versatile in their applications, capable of grinding materials such as coal, pigments, and feldspar for pottery. Grinding can be performed either wet or dry, with wet grinding typically conducted at lower speeds. One notable application of rubber balls in ball mills is in the blending of explosives. Furthermore, ball milling has proven effective in enhancing solid-state chemical reactivity in systems with multiple components and in the production of amorphous materials.

Our company specializes in supplying high-quality manganese steel and high chromium alloy wear plates for ball mills. These wear plates are engineered to withstand extreme conditions, offering superior resistance to abrasion and impact. Manganese steel wear plates are known for their exceptional hardness and durability, making them ideal for heavy-duty grinding operations. High chromium alloy wear plates, on the other hand, provide excellent corrosion resistance and are particularly suited for environments where chemical reactivity is a concern. Both types of wear plates are designed to maximize the efficiency and longevity of your ball mill operations.